Manufacturing Wheels

Design, Engineering & Testing

At Forza Performance Group, design is where every forged wheel begins. We focus on making wheels that are strong, lightweight, and look great. But design isn’t everything — your wheels also need to fit your car properly. That means they must clear the fenders, work with your brakes, and match your vehicle’s overall setup.

Every car is different in size, shape, and clearance. That’s why we measure each vehicle carefully and build our forged wheels to fit that exact model. This allows us to maximize the depth of the wheel (concavity) and ensure the best possible appearance and fitment.

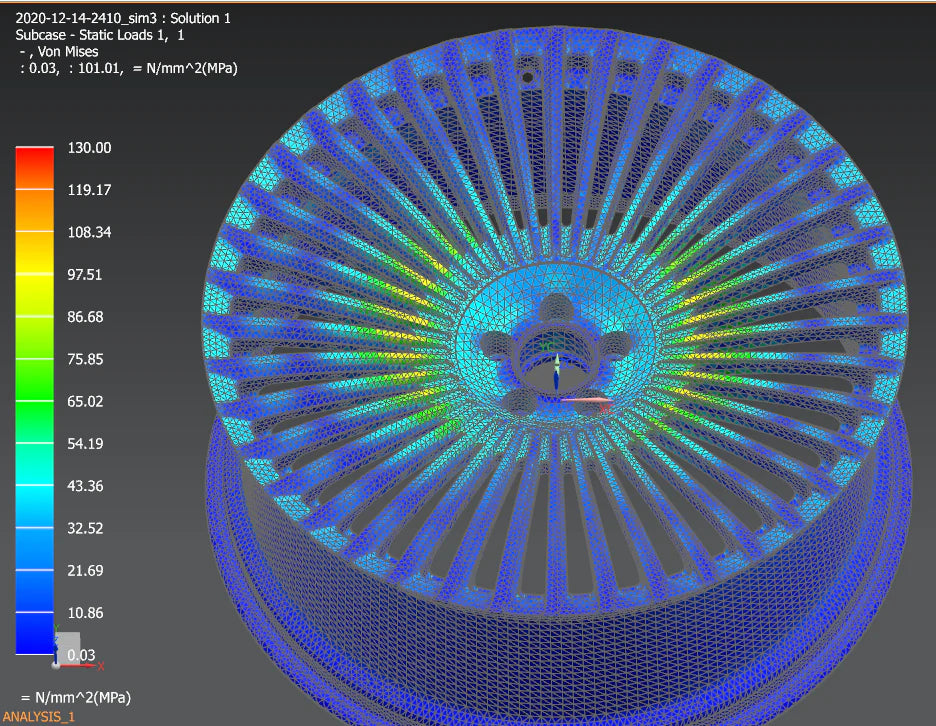

Each wheel goes through a full development process. We test our designs using industry standards like SAE, JWL, VIA, and TÜV, and we also use computer simulation (FEA) to check how the wheel will handle real-world forces such as cornering, bumps, and acceleration

Once the design is approved, it’s turned into a precise machining program (G-Code) so the CNC machines can cut the wheel exactly as intended.

Forging & Materials

Quality wheels start with quality materials. We use 6061-T6 aluminum forged in a modern, certified facility. The forgings are inspected using ultrasound and formed using presses up to 12000 tons. Afterward, they go through a T6 heat-treatment process, which greatly increases strength.

This creates a very strong and reliable base for the final wheel.

6061-T6 aluminum forgings ensure high quality forged wheel. This provides a superior foundation that guarantees durability and a reliable, high-performance product that meets our team's highest standards.

CNC Machining

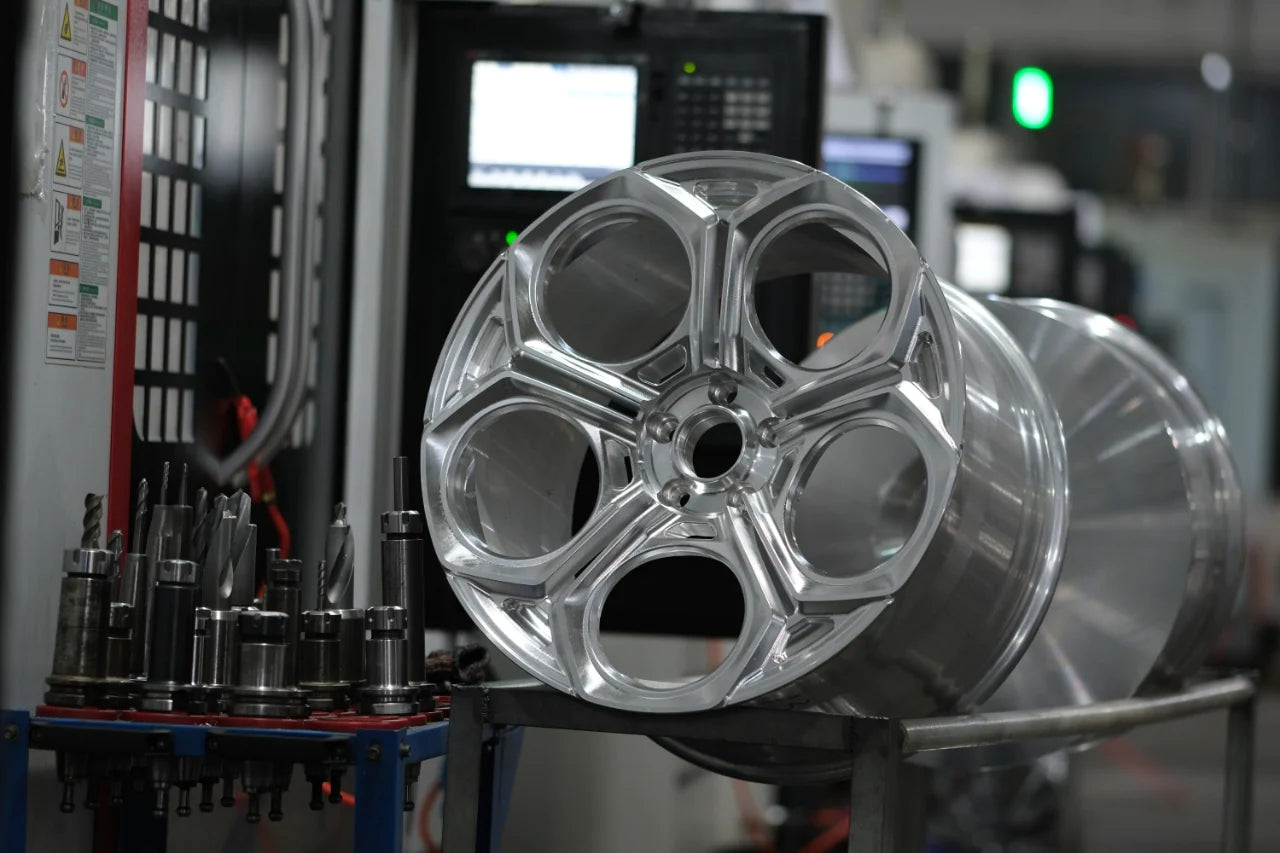

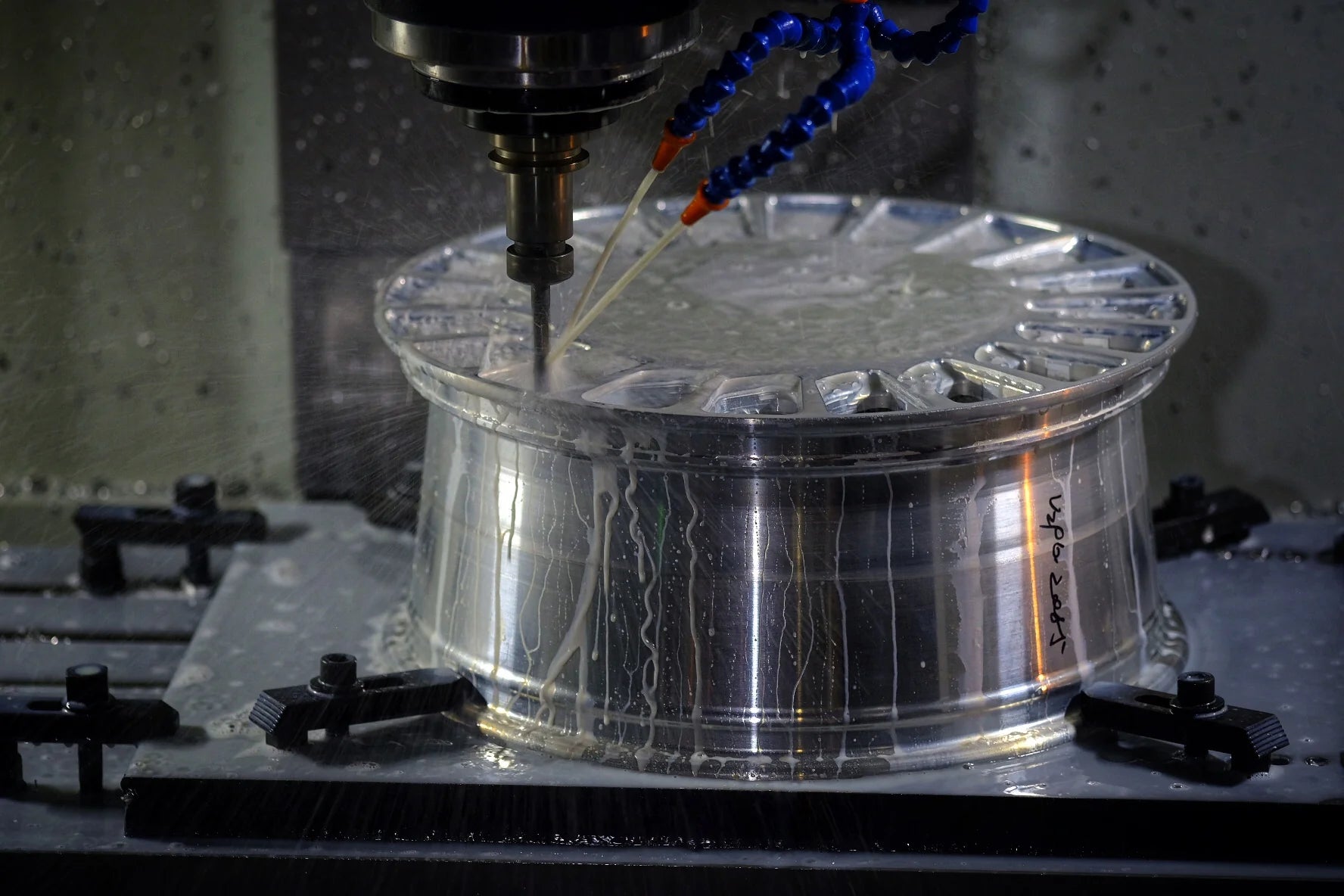

At this stage, the forged block of aluminum is shaped into the actual wheel. We use a dedicated set of CNC machines to cut the design with high accuracy. Lathes ensure the wheel is perfectly round, and milling machines carve the face and other details.

After the front side is cut, the wheel is flipped and the back is machined. This includes milling out pockets to reduce weight without affecting strength.

Post-milling and hand preparation

After machining, each wheel goes through several stages of smoothing, hand-finishing, and polishing. Our team carefully cleans up every edge and surface so the wheel looks perfect before coating.

Finishing (Painting & Coating)

We use a combination of powder coating and paint to achieve a strong, long-lasting finish. Each wheel goes through a multi-step process:

powder coat → bake → paint → bake → clear powder coat → final bake

This creates a durable finish that resists chipping and corrosion while giving the wheel a clean, premium look.

Every wheel is inspected carefully at each step to make sure the color, surface, and coating quality are consistent.

Quality control

Before the wheels are packaged, our QC team checks every important measurement based on the engineering drawings. One of the most important checks is “runout,” which basically measures how perfectly round the wheel is when it spins. All Forza Performance Group wheels must pass strict runout tolerances before they leave our facility.